(1) Tungsten Carbide rolls

Main grades of carbide rolls

Grade | Chemical Composition % | Hardness (HRA) | Density (g/cm3) | Transverse Rupture Strength (MPa) | Compressive Strength (MPa) |

YGH05 YGH10 YGH30 YGH45 YGH55 YGH60 YGR30 YGR45 YGR55 YGR60 PA10 PA20 PA30 | Co 6 8 15 20 26 30 Co+Ni+Cr 15 20 26 30 Co+Ni+Cr 10 15 20 | 88.5 87.8 84.8 83.6 82.1 80.8 84.2 81.7 79.5 79.1 86 84.4 82 | 14.91 14.71 13.99 13.55 13.03 12.72 13.98 13.52 13.01 12.71 14.52 13.95 13.47 | 2620 2870 2870 2840 2700 2730 2900 2720 2630 2630 2750 2910 2760 | 3700 3500 3300 3100 3000 3000 3200 3000 2800 2600 3800 3700 3300 |

Note:The above property data are typical.

Popular size of carbide rolls

O.D | I.D | Thickness |

145-450 | 87-280 | 62-210 |

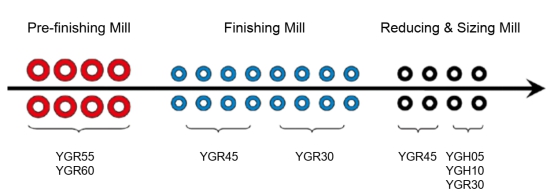

(a) Rolling mills with reducing & sizing mill

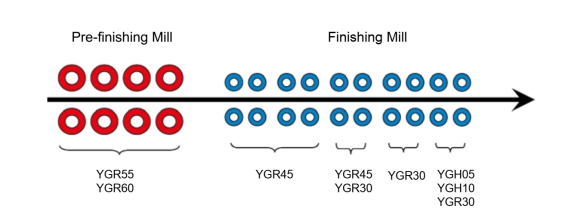

(b)Rolling mills with reducing & sizing mill

(c)The grades YGR55 and YGR60 are also for hot rolling rebars

(2) Tungsten Carbide Composite type Roll Rings

(a)Grade of composite cemented carbide roll rings

Grade | Element content % | Physical and mechanical properties | |||

Co+Ni | WC and others | Hardness HRA | Transverse rupture strength (Sample B) MPa | Density g/cm3 | |

YGR55 | 26 | 74 | ≥79.0 | ≥2400 | 12.93~13.13 |

YGR60 | 30 | 70 | ≥78.5 | ≥2200 | 12.63~12.83 |

Cemented carbide roll ring is a kind of tool material which consists of tungsten carbide and cobalt with high hardness and. wear resistance.To take advantage of high wear resistance,long life and high efficiency of cemented carbide roll rings during the high speed rolling,attention should be paid as follows when purchasing and using cemented carbide roll rings:

(b)Grades selection

An overall understanding of the properties of cemented carbide grades is a basis for correctly selecting the grades for roll rings used in the stands of rolling mills and an optimal combination of grades is required for the various stands of rolling mills.

Parameters

Grade | Chemistry% | Mechanical Property | Physical property | |||||

Co+Ni | WC | Hardness HRA | Transverse rupture strength N/mm2 | Compressive strength N/mm2 | Young Modulus KN/mm2 | Density g/cm3 | Heat conductivity sec/℃ | |

YGH20 | 10 | 90 | ≥86.0 | ≥2500 | 3500 | 560 | 14.2~14.5 | 0.20 |

YGH25 | 12 | 80 | ≥84.0 | ≥2300 | 3400 | 550 | 14.0~14.3 | 0.21 |

YGH30 | 15 | 85 | ≥83.5 | ≥2520 | 3300 | 540 | 13.8~14.2 | 0.20 |

YGH40 | 18 | 82 | ≥83.0 | ≥2570 | 3200 | 500 | 13.4~13.9 | 0.19 |

YGH45 | 20 | 80 | ≥82.0 | ≥2570 | 3100 | 480 | 13.3~13.9 | 0.18 |

YGH55 | 26 | 74 | ≥81.0 | ≥2570 | 3000 | 450 | 12.6~13.2 | 0.17 |

YGR25 | 12.5 | 87.5 | ≥83.0 | ≥2270 | 3300 | 540 | 14.0~14.3 | 0.22 |

YGR30 | 15 | 85 | ≥83.0 | ≥2360 | 3200 | 530 | 13.8~14.3 | 0.20 |

YGR40 | 18 | 82 | ≥82.0 | ≥2400 | 3200 | 430 | 13.5~13.9 | 0.20 |

YGR45 | 20 | 80 | ≥80.5 | ≥2250 | 3000 | 480 | 13.4~13.9 | 0.18 |

YGR55 | 25 | 75 | ≥79.0 | ≥2400 | 2800 | 420 | 12.9~13.4 | 0.17 |

YGR60 | 30 | 70 | ≥78.5 | ≥2200 | 2600 | 300 | 12.6~13.1 | 0.16 |

YGH05 | 6 | 94 | ≥83.0 | ≥2360 | 3200 | 530 | 13.8~14.3 | 0.20 |

YGH10 | 8 | 92 | ≥82.0 | ≥2400 | 3200 | 430 | 13.5~13.9 | 0.20 |

PA10 | 10 | 90 | ≥80.5 | ≥2250 | 3000 | 480 | 13.4~13.9 | 0.18 |

PA20 | 15 | 85 | ≥79.0 | ≥2400 | 2800 | 420 | 12.9~13.4 | 0.17 |

PA30 | 20 | 80 | ≥78.5 | ≥2200 | 2600 | 300 | 12.6~13.1 | 0.16 |

Note:1.Physical & mechanical properties are for reference only and their variations are as per national of enterprises' standards.

2.Related data.

(c)Recommended Applications

Grade | Recommended applications |

YGR20 | High wear resistance and corrosion resistance.Used in the last 1-2 stands of finishing mils. |

YGR25 | High wear resistance and corrosion resistance.Used in the last 1-3 stands of finishing mils. |

YGR30 | Good toughness wear resistance corrosion resistance and thermal crack resistance.Used in the middle and rear stands of finishing mills. |

YGR40 | Good toughness end thermal crack resistance good tor general purposes.Used in most stands of the finishing mills and in the rear stands of common mills. |

YGR45 | Good toughness and thermal crack resistance.Used in the front stands of finishing mills. |

YGR55 | Good impact resistance.Used in the stands of pre-finishing rolling mi for hat rolling ribbed steel bars and they can be machined with turning and milling. |

YGR60 | Good impact resistance. Used for hot rolling ribbed steel bars and in the first and second stands of pre-finishing rolling mils. |

YGH05 | The WC content of the grades is higher than that of other roll grades used in high-speed wire mills.They have higher hardness and wear resisance properties Because tungsten carbide has exceilent heat transfer property. The high WC content will increase the ability of hot cracking resistance.These characteristics of the grades can make the rolled wires with regular shape and good surface quality.At the same time,the high fracture toughness make them enough to bear mechanical stress during rolling. |

YGH10 |

(d)grades recommended for use in different stands

Grade series | YGR | YGH | |||||||

Mill classes | A | B | C | A | B | C | |||

Stands of prefinishing mill | 1 | 1 | YGR60 | YGR60 | YGR60 | YGH60 | YGH60 | YGH60 | |

2 | 2 | YGR60 | YGR60 | YGR60 | YGH60 | YGH60 | YGH60 | ||

3 | 3 | YGR55 | YGR55 | YGR60 | YGH55 | YGH55 | YGH55 | ||

4 | 4 | YGR55 | YGR55 | YGR55 | YGH55 | YGH55 | YGH55 | ||

Stands of finishing mill | 5 | 5 | YGR40 | YGR45 | YGR45 (YGR55) | YGH45 | YGH55 | YGH55 | |

6 | 6 | YGR40 | YGR45 | YGR45 | YGH45 | YGH55 | YGH55 | ||

7 | 7 | YGR40 | YGR45 | YGR45 | YGH40 | YGH45 | YGH55 | ||

8 | 8 | YGR40 | YGR45 | YGR45 | YGH40 | YGH40 | YGH55 | ||

9 | ○ | ○ | YGR30 | YGR40 | YGR45 | YGH30 | YGH40 | YGH45 | |

10 | ○ | ○ | YGR30 | YGR40 | YGR45 | YGH30 | YGH40 | YGH45 | |

11 | ○ | ○ | YGR30 | YGR40 | YGR40 | YGH30 | YGH40 | YGH45 | |

12 | ○ | ○ | YGR30 | YGR40 | YGR40 | YGH30 | YGH40 | YGH45 | |

13 | ○ | ○ | YGR20 (YGR25) | YGRYGR40 (YGR30) | YGR40 | YGH20 (YGH25) | YGH25 (YGH30) | YGH40 | |

14 | ○ | ○ | YGR20 (YGR25) | YGR25 (YGR30) | YGR40 | YGH20 (YGH25) | YGH25 (YGH30) | YGH40 | |

Stands for reducing and sizing mill | 15 | ○ | ○ | YGR40 | YGR45 (YGR40) | YGR45 | YGH40 | YGH45 (YGH40) | YGH45 |

16 | ○ | ○ | YGR40 | YGR45 (YGR40) | YGR45 | YGH40 | YGH45 (YGH40) | YGH45 | |

17 | ○ | ○ | YGR20 (YGR25) | YGR30 (YGR25) | YGR40 (YGR30) | YGH20 (YGH25) | YGH30 (YGH25) | YGH40 (YGH30) | |

18 | ○ | ○ | YGR20 (YGR25) | YGR30 (YGR25) | YGR40 (YGR30) | YGH20 (YGH25) | YGH30 (YGH25) | YGH40 (YGH30) | |

Note Classes A,B,C means excellent good, bad working conditions of rolling mills respectively. The grade in the bracket is the second choice.

ZALO